What makes a Compass Pool tougher than an ordinary fibreglass pool?

When Compass Pools first introduced ceramic composite technology to the swimming pool industry in the mid-90s, it quickly gained worldwide recognition. Over the years, we have solidified our reputation as global leaders and pioneers in this field.

When Compass Pools first introduced ceramic composite technology to the swimming pool industry in the mid-90s, it quickly gained worldwide recognition. Over the years, we have solidified our reputation as global leaders and pioneers in this field.

Our unique, patented technology significantly enhances the structural integrity of our pools, giving Compass Pools the ability to provide customers with the assurance that our products are tailored to meet their specific site requirements.

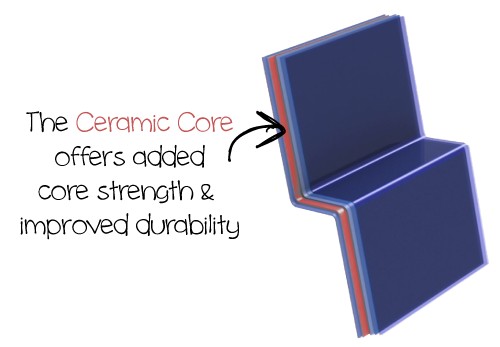

The key to the durability and success of a Compass Pool lies in its patented ceramic composite design.

In the early 90s, our research and development team at Compass set out to create a pool that was exceptionally strong and reliable, allowing us to offer an extended structural guarantee and a superior interior surface guarantee to our customers.

It was well known that using vinyl ester resin during manufacturing would greatly enhance a pool shell’s resistance to water. This is because vinyl ester resin is 50 times more resistant to hydrolysis by water than polyester resin, which is commonly used in fibreglass pool construction.

However, at Compass, we aimed to go beyond the industry standards. Our goal was to develop a fibreglass composite pool that would offer our customers greater longevity.

Our team returned to the drawing board, determined to find the best solution for our customers.

After extensive research, we developed a technology that combined vinyl ester resin with ceramic microspheres. This innovation resulted in a lightweight composite core that significantly enhanced the structure and performance of our fibreglass pools. Similar composite materials are used in aerospace, high-performance trains, and racing boats. For our pools, this blend of ceramic microspheres and vinyl ester resin also required the modification of our fibreglass spraying equipment, a process that became part of our patented method.

.png)

-556-913.png)